29 Nov 2021

Is green hydrogen our great hope, or a non-starter whose increasingly vigorous promotion is distracting us from the crucial task at hand? What hydrogen work is underway in Aotearoa – and where do engineers fit in?

When the next America’s Cup is raced, the yachts won’t be the only cutting-edge technology on the water, with Team New Zealand recently unveiling plans to develop a hydrogen-powered chase boat for 2024. Sleekly futuristic and 100 percent emissions-free, it could be a spectacular advertisement for what many argue will be a key tool in moving the planet to net zero carbon. Among hydrogen-sceptics, however, it’s likely to be seen as another instance of wishful thinking flying in the face of the facts.

Green hydrogen uses renewable electricity to split water into its two component molecules, hydrogen and oxygen. Hydrogen gas is then stored and used like a battery to generate electricity when required. Advantages include the long-term storage of potential renewable energy. Disadvantages include the significant energy lost through the electrolysis.

The Government’s hydrogen roadmap is expected next year, but based on a 2019 Ministry of Business, Innovation and Employment (MBIE) green paper it clearly sees a role for green hydrogen in decarbonising heavy transport and industrial processes. That paper also suggests there could be an export opportunity for New Zealand. A memorandum of cooperation on green hydrogen was signed with Singapore in July, following similar agreements to develop expertise with Japan and South Korea.

Ballance Agri-Nutrients’ manufacturing plant in Kapuni, Taranaki. Image: Ballance Agri-Nutrients

Meanwhile, the private sector is rapidly rolling out green hydrogen projects. Backed by $20 million from the Provincial Growth Fund, Hiringa Energy and Ballance Agri-Nutrients are building a $50 million wind-powered hydrogen facility at Ballance’s Kapuni plant in South Taranaki. It will initially be used to produce ammonia and urea, but with the idea that as the market develops hydrogen can be diverted to fuel heavy transport.

On that front, Hiringa Energy is now moving to the construction phase of its national green hydrogen refuelling network which comes online in 2022. Elsewhere, the Tuaropaki Trust and Japan’s Obayashi Corporation have completed a green hydrogen facility at the Trust’s geothermal plant near Taupō; FirstGas has committed to introducing 20 percent hydrogen (by volume) into its gas pipelines starting in 2030. Ports of Auckland plans to build an electrolyser for the port, and its refuelling station is already powering

New Zealand’s first hydrogen fuel cell bus. Energy companies Contact and Meridian have committed $2 million to investigate a hydrogen facility in Southland that could use the electricity made surplus if and when the Tiwai Point smelter closes.

Clearly, it’s still early days – 95 percent of hydrogen is “brown hydrogen”, produced from coal and natural gas. There’s an argument that the government will have to financially support trailblazing projects to build the economic case for using green hydrogen over fossil fuels. But proponents maintain we’re ideally suited for a hydrogen future given our stock of renewable energy sources, adding that New Zealand’s emissions profile rules out electrification as a silver bullet.

Our diesel truck fleet, for instance, accounts for only six percent of total vehicle kilometres travelled but is responsible for almost a quarter of road transport emissions, and that proportion will grow as freight demand increases and the passenger fleet decarbonises. Many believe electrifying large long-distance electric trucks at scale is unlikely.

Export opportunity?

Dr Linda Wright, Chief Executive of the New Zealand Hydrogen Council, whose growing membership of more than 40 organisations includes industry, government and academic organisations, argues we need options to achieve our climate targets.

“Electrifying the entire economy isn’t feasible, so we need a range of solutions and they need to be integrated across the energy system,” she says, citing heavy transport and the need to reduce the use of coal for industrial processing heat, along with dry-year storage issues, as making a compelling case for green hydrogen.

Linda is also adamant that there is “an incredible export opportunity” for New Zealand, with “trillions” being invested globally in developing a future for green hydrogen as a tradeable commodity. It’s at the fledgling stage, she concedes, but already companies such as Kawasaki and Mitsubishi are starting to export hydrogen.

“New Zealand is in a position where it can participate in that global trade with our international partnerships. What that would offer is production of green hydrogen at scale, which would be beneficial for New Zealand Inc in terms of off-take agreements for reduced cost production and distribution of zero emission hydrogen to help us decarbonise domestically,” she says, adding that there’s a big role to be played in this future by “capable, technically astute” engineers.

“We’ve got some who are very familiar with hydrogen, but we’ll need a lot more across the hydrogen supply chain.”

Electrifying the entire economy isn’t feasible, so we need a range of solutions and they need to be integrated across the energy system. – Dr Linda Wright

Dr Jim Hinkley MEngNZ, Senior Lecturer in Renewable Energy Systems at Victoria University of Wellington, sees the challenge for hydrogen as being the immaturity of the market rather than anything technical.

“We’re only just starting to build large-scale electrolysers and the biggest in the world is currently 20 megawatts, whereas Huntly is 450 megawatts. But it is coming,” says Jim, who thinks an obvious source for producing green hydrogen in this country will be geothermal, along with wind.

As for demand, he backs the prospect of New Zealand becoming an exporter to energy-poor countries such as South Korea and Japan, where thermal power generation using LNG is on borrowed time.

In transport? Trucks and buses are obvious candidates for hydrogen fuel cells, but he also includes passenger vehicles.

“It makes a lot of sense to have batteries around cities, but the periodic table doesn’t lend itself to using batteries for long journeys. Hydrogen gives you all the benefits of electric vehicles, but with much better range,” says Jim, who doesn’t subscribe to predictions

of inexorable battery improvement.

“Yes, they will get a bit better, and maybe you could make larger batteries that charge really quickly and will be 30 percent lighter than today’s, but I don’t know how you’re going to have an electricity network to support that. Whereas with hydrogen, the decoupling of refuelling and the creation of the hydrogen is a very important factor.” As well, refuelling time is on a par with petrol.

Hydrogen gives you all the benefits of electric vehicles, but with much better range. – Dr Jim Hinkley

New Zealand's first hydrogen fuel cell bus by Global Bus Ventures. Image: Auckland Transport

Highlighting the shortcomings

Others argue that all of this is fanciful. Among other shortcomings, hydrogen is an inefficient vector, having to go from “wire to gas to wire” as one observer put it. For vehicles, that means much less of the energy needed to produce it ends up “in the tank”, compared with an EV.

The most prominent engineering voice highlighting the shortcomings of green hydrogen is University of Canterbury Professor of Mechanical Engineering Susan Krumdieck, author of Transition Engineering: Building a Sustainable Future. Susan’s view is that the world needs to dramatically downshift its energy use, and that many touted sustainability solutions are merely fiddling at the edges.

In the case of hydrogen, it fails on several fronts. In a 2009 analysis with Shannon Page, she quantified elements such as energy conversion, transmission and energy service demand conversion, and found that hydrogen didn’t pass muster on the basis of system-level efficiency.

Her scepticism is shared by Christchurch-based process engineer Johann Land, who did his doctorate under Susan at Canterbury. Made and used on-site, green hydrogen does have a role in decarbonising something like the production of fertiliser, he argues. But on the bigger stage, it “always underperforms” compared with electricity. As for decarbonising heavy transport, says Johann, the answer is not hydrogen, but trains.

“We need to rethink our industries so they would be alongside rail, and massively invest in rail infrastructure.”

Projects underway

This argument over green hydrogen is playing out even as the market and the science are generating potential solutions. In New Zealand, innovative research includes a GNS Science-led project investigating direct sunlight-to-hydrogen systems to enable off-grid generation, and using wastewater and seawater in the catalysis process.

Another project involves cryocooler developer AFCryo, the Christchurch-based outfit that Team New Zealand is working with on its chase boat. In collaboration with United Kingdom-based electrolyser manufacturer Clean Power Hydrogen, AFCryo is looking to develop a cheaper and more efficient on-demand green hydrogen production system. There’s also research led by

Dr Chris Bumby at Victoria University of Wellington’s Robinson Research Institute investigating a zero-carbon method of reducing ironsand. Backed by $6.5 million of MBIE Endeavour funding over five years, the process replaces coal with green hydrogen, and could provide a solution to the heavy environmental cost of steelmaking.

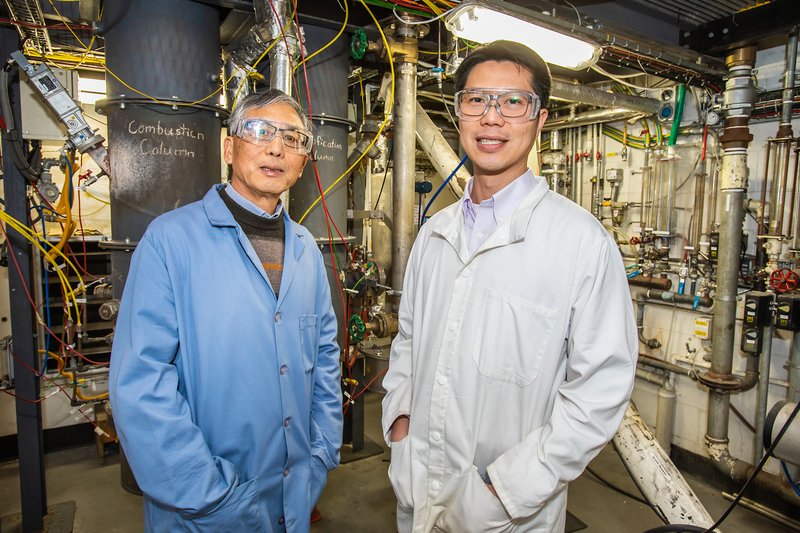

Meanwhile, University of Canterbury engineers are focused on finding a way to use renewable biomass to generate green hydrogen. Professor Shusheng Pang FEngNZ is leading the project, which aims to use waste from forest harvesting and wood processing as well as low-quality logs as a hydrogen feedstock.

University of Canterbury Chemical and Process Engineers Professor Shusheng Pang FEngNZ(left) and Associate Professor Alex Yip MEngNZ. Image: University of Canterbury

The team is working with Lower Hutt-based Hot Lime Labs to capture carbon dioxide, and is developing a unique gasification technique (using steam) and a novel catalyst to enhance yield. Developed by Canterbury’s Associate Professor Alex Yip MEngNZ, the catalyst ensures the efficient conversion of carbon monoxide and methane in the gas to hydrogen and carbon dioxide.

Shusheng says the research, which is supported by a $1 million MBIE grant, is potentially a win-win, tackling inefficiency in the forestry industry while providing a method to use in parallel with electrolysis to boost production of hydrogen and maintain a secure supply.

Generating required renewable electricity for green hydrogen takes time and needs a lot of investment, and solar and wind are not always available, he says.

“With biomass you can continually produce hydrogen and know it’s a reliable feedstock. New Zealand has a lot of wood waste and low-quality logs, and we could also use biowaste from the agricultural sector.”

To date, the gasification and carbon capture technology is proven, with the catalyst still to be tested at laboratory scale. Assuming it passes muster, Shusheng reckons it will take three to five years to integrate the technologies into one system and prove it at demonstration scale, and a decade or more to achieve commercial production. Eventually, however, “we could have a similar share as electrolysis”, he says.