The Rotowaro Carbonisation Plant, south-west of Huntly, opened in 1931. The plant took slack coal waste from the Waikato coalfield and converted it to fuel pellets called carbonettes, as well as into other useable by-products such as creosote, tar, pitch, gas and light oil.

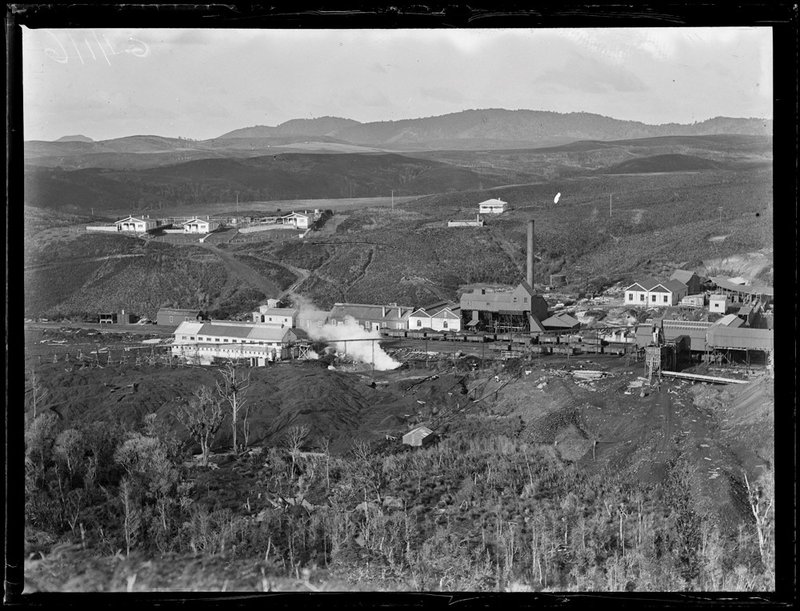

Sir George Grey Special Collections, New Zealand Herald Glass Plate Collection, Auckland Libraries, 1370-226-15. Photographer, W. B. Beattie.

The problem of slack coal

Slack coal, fragments of coal and coal dust, were a disposal problem at coal mines. This was recognised as a national problem in New Zealand from 1891 when large quantities of coal fragments were being dumped. Although attempts were made to make briquettes at the Brunner mine near Greymouth, in Christchurch and at Seddonvillie north of Westport, they were not very successful and did not last.

Waikato coal, a major source for the North Island, was mined at Rotowaro and other nearby mines. The coal is described as sub-bituminous B rank of the A.S.T.M. classification with low sulphur and ash content. Rotowaro coals tend to break down to slack when exposed to the weather. At Rotowaro up to 45% of the mined coal became slack waste and although some of it was used at Kings Wharf Power Station in Auckland until it closed, much remained to be dumped.

Rotowaro Carbonisation Plant

Experiments in 1924 to make carbonettes recognised that a binding agent and heat would be required. Samples of Waikato coal were sent to England, Belgium and Germany. The German Lurgi process being used in Canada, USA, Greece, Hungary and Germany was chosen as the most suitable.

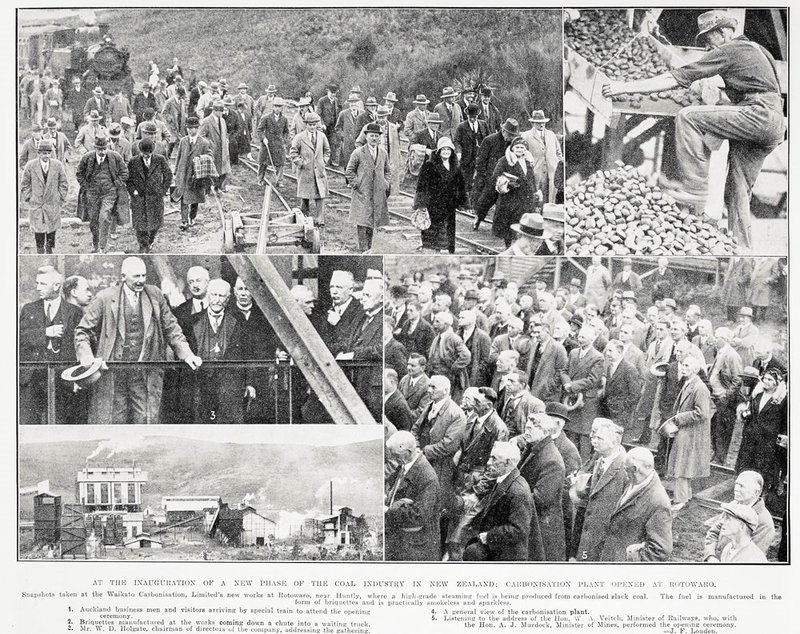

The specialised equipment needed was imported and a carbonisation plant constructed at Rotowaro. The official opening of the plant on 10 June 1931 by the Minister of Railways the Hon. W. A. Veitch and the Minister of Mines the Hon A. J. Murdoch took place in front of 200 guests, many of whom travelled by special train from Auckland. The plant was the first of its kind in the southern hemisphere.

The Lurgi process

In the Lurgi process, slack coal is carbonised at a low temperature leaving between 7%-10% of volatile matter, resulting in a semi-coke.

At Rotowaro, slack coal was fed by conveyor into a 1,000-ton capacity coal bunker. An electric separator then removed any pieces of iron and steel from the slack. An insulated metal furnace produced the coal gas necessary for starting the two Lurgi Spulgas retorts, which were then externally heated to a maximum temperature of 650 degrees Celsius. The low temperature carbonisation created an almost smokeless fuel described as semi-coke. Tar, oil and pitch were produced as by-products. Carbonettes were created from the semi-coke, with the pitch used as a binder.

The retorts operated continuously 24 hours per day seven days per week for 10 months of the year.

"At the inauguration of a new phase of the coal industry in New Zealand: Carbonisation plant opened at Rotowaro." Sir George Grey Special Collections. Auckland Libraries AWNS-19310617-46-1

Supply and demand

Initially the Railways Department was very supportive of the carbonisation plant and carbonettes were used in locomotives. By 1934 however, carbonettes were found not to be suitable for locomotives and the contract for their supply was not renewed. The high cost of carbonettes may also have influenced the Railways Department.

Initially, demand for carbonettes failed to meet expectations, but by 1937, helped by government advertising, demand had grown to outstrip supply.

During the petrol shortages created by World War II, gas producers were used on cars and light trucks. To meet demand, the company produced 1,000 tons of char - the solid product from the initial stage of combustion - per month under the name of ‘Waicarbo’.

By the mid-1950s as well as carbonettes, screened carbonised coal, creosote, pitch and gas were being produced. By 1962 demand was dropping and in 1964 when the retorts needed to be replaced the cost was deemed too high. Other products continued, with New Zealand Steel taking char for their steel production process.

On 7 March 1974 an explosion occurred in the distillation building. Repairs were undertaken but the production of carbonettes, creosote and pitch had to be stopped. The production of char continued. In 1987 another explosion occurred at the retort building followed by a major fire, causing the plant to close. The company went into liquidation.

Contaminated Site

The site had spread contamination over a wide area because it was established when there weren’t any controls or controlling authority. Contaminated waste continued to discharge to the Awaroa Stream and even after the company was fined in 1976, they did not comply with their water right. By 1981 the company stopped discharging to the stream by creating three waste ponds that eventually overtopped. They tried biological treatment of the pond water, but this was not successful.

By 1990, with the company in liquidation and the banks of the ponds showing signs of collapse, action became necessary. The Waikato Regional Council on behalf of the Government undertook the work of moving 11,000 cubic metres of contaminated liquid from the ponds to Kinleith Paper Mill where it was incinerated. The remaining pond sludge was treated by bioremediation.

From 1992, Coal Corp began expanding their opencast mine to the east and south-east of the carbonisation works and some of the remaining buildings in the Rotowaro Industrial Precinct were demolished.

In 2003, site remediation continued with steps undertaken to identify and remove remaining contaminants.

The remains of the Lurgi retort building with the original brick cladding on the left half of the building. Copyright: Heritage New Zealand Pouhere Taonga. Photo by F. van der Heijden, 12/05/2008.

More Information

Heritage recognition

This place has been recognised by Heritage New Zealand as a Category 1 historic place (List no.7013) Rotowaro Carbonisation Works: New Zealand Heritage List/Rarangi Korero information.

Further reading

Williams, G.J. (ed.) “Economic geology of New Zealand.” Australasian Institute of Mining and Metallurgy. Monograph 4. (1974).

Access

There is no public access to the site

Location

Rotowaro Carbonisation Works

Entry by John La Roche

Page last updated 16 September 2020